Collaborative Robotics: Reshaping Industrial Workflows

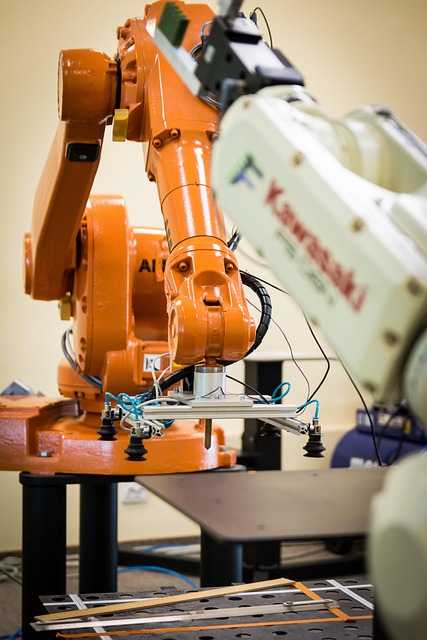

In today's rapidly evolving industrial landscape, a groundbreaking technology is transforming the way humans and machines interact on factory floors. Collaborative robotics, or cobots, are emerging as a game-changing solution that bridges the gap between traditional automation and human expertise. This innovative approach is revolutionizing industrial processes, enhancing productivity, and creating safer work environments.

The Evolution of Human-Robot Collaboration

The concept of collaborative robotics has its roots in the early 2000s, when researchers began exploring ways to create safer, more versatile robotic systems that could operate in close proximity to human workers. Traditional industrial robots, while highly efficient, were often confined to caged areas due to safety concerns. This limitation restricted their flexibility and applicability in many manufacturing scenarios.

As sensor technologies and artificial intelligence advanced, it became possible to develop robots that could detect and respond to human presence, paving the way for true collaboration. The first commercially available cobot was introduced in 2008, marking the beginning of a new era in industrial automation.

Key Features of Collaborative Robots

Collaborative robots are distinguished by several key features that set them apart from their traditional counterparts:

-

Enhanced Safety: Cobots are equipped with advanced sensors and force-limiting technology, allowing them to detect human presence and adjust their behavior accordingly. This ensures safe operation without the need for physical barriers.

-

Ease of Programming: Unlike complex industrial robots, cobots can be easily programmed through intuitive interfaces, often requiring no specialized coding knowledge.

-

Flexibility: Cobots are typically lightweight and mobile, allowing for easy redeployment across different tasks and production lines.

-

Precision and Consistency: While working alongside humans, cobots maintain high levels of accuracy and repeatability, ensuring consistent quality in production processes.

-

Scalability: Collaborative robots can be easily integrated into existing workflows, making them suitable for both small-scale operations and large manufacturing facilities.

Applications Across Industries

The versatility of collaborative robots has led to their adoption across a wide range of industries:

-

Automotive Manufacturing: Cobots assist in tasks such as assembly, quality inspection, and material handling, working in tandem with human workers to improve efficiency and ergonomics.

-

Electronics Production: In the fast-paced electronics industry, cobots excel in precise assembly tasks, component insertion, and testing procedures.

-

Food and Beverage Processing: Collaborative robots are increasingly used in packaging, palletizing, and quality control processes, maintaining hygiene standards while boosting productivity.

-

Aerospace: The aerospace sector leverages cobots for intricate assembly tasks, composite layup, and non-destructive testing, where precision is paramount.

-

Healthcare and Pharmaceuticals: In these sensitive industries, cobots assist in laboratory automation, drug dispensing, and even surgical procedures, enhancing accuracy and reducing human error.

Economic Impact and ROI

The implementation of collaborative robotics has demonstrated significant economic benefits for adopters. Studies have shown that cobots can increase productivity by up to 50% in certain applications, with ROI often achieved within 12 to 18 months. This rapid return on investment makes cobots particularly attractive to small and medium-sized enterprises (SMEs) that may have previously found traditional automation solutions out of reach.

Moreover, by taking over repetitive or ergonomically challenging tasks, cobots allow human workers to focus on higher-value activities that require creativity, problem-solving, and decision-making skills. This shift not only improves overall productivity but also enhances job satisfaction and reduces the risk of work-related injuries.

Practical Insights for Implementing Collaborative Robotics

• Conduct a thorough assessment of your current workflows to identify tasks suitable for human-robot collaboration.

• Invest in comprehensive training programs for employees to ensure smooth integration and maximize the benefits of cobot technology.

• Start with pilot projects to gain experience and build confidence before scaling up implementation.

• Consider the total cost of ownership, including maintenance and potential upgrades, when evaluating the long-term value of cobot investments.

• Leverage data analytics capabilities of cobots to gain insights into process efficiency and identify areas for continuous improvement.

As collaborative robotics continues to advance, it promises to reshape the future of industrial operations. By fostering a harmonious relationship between human workers and robotic systems, this technology is not just improving efficiency and safety; it’s creating a new paradigm for manufacturing excellence. As industries worldwide embrace this collaborative approach, we can expect to see even more innovative applications and transformative impacts in the years to come.